Dust can pose a serious fire risk in a variety of industrial facilities. It’s important for businesses to understand the types of dust they may encounter, along with the factors that create a potentially combustible situation.

There are two broad categories of industrial dust. The first relates to dust that is a direct product of processing operations, such as in pharmaceutical or cereal manufacturing. “You normally wouldn’t even call this dust; you would refer to this as powder,” says Dr. Chris Cloney, managing director and lead researcher for DustEx Research, a company with worldwide focus on increasing awareness of combustible dust hazards.

The second type of dust is a byproduct of the material being processed. “As you dump, convey or process the material, it often breaks down and leaves a dust-like substance,” Cloney says. This substance accumulates in and around the equipment before eventually spreading further into the facility. If left unattended, this type of dust creates significant risk for a facility.

WHAT MAKES DUST COMBUSTIBLE?

The National Fire Protection Association (NFPA) once said that in order to be combustible, dust had to be of a specific particle size: 420 microns or smaller, which is smaller than half a millimeter. That seemed to make a lot of sense. Think about firewood, for instance. A log will burn but kindling burns a lot faster. The smaller the kindling, the faster it burns.

Nowadays, however, the NFPA doesn’t specify particle size. “Any particulate matter that provides a deflagration hazard is deemed combustible,” Cloney points out. “This new definition has been picked up by both OSHA and the Canadian Center for Occupational Health & Safety.”

There is a reason why this new definition of “combustible dust” doesn’t focus on particle size. Not all industrial dust is necessarily combustible. The dust itself, regardless of size or shape, must be reactive enough to be capable of causing a flash fire. With the help of a professional, there are various tests a facility can conduct to determine if the dust it is dealing with is indeed combustible.

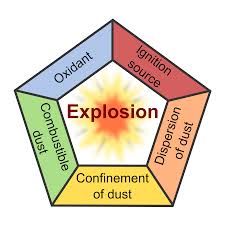

Additionally, other factors must be present to create a combustible dust hazard. This is referred to as the Dust Explosion Pentagon, which includes five essential elements:

- Fuel (dust)

- Oxidizer (oxygen in the air)

- Ignition Source (i.e. welding spark, hot screw)

- Dispersion

- Confinement

Dispersion is when dust gets into the air. Generally speaking, dust wants to settle to the ground. But in certain industrial settings where there is dumping and conveying of material, the dust is constantly being thrown into the air. If that cloud is close to an ignition source, it could cause a flash fire.

The fifth element of the Dust Explosion Pentagon is confinement. When a flash fire breaks out and is contained in a confined area, pressure can build up to the point that an explosion occurs. “Think of confined spaces such as hoppers, dust collectors and silos,” Cloney says.

THE CONSEQUENCES OF NON-COMPLIANCE

NFPA 652 is a collection of guidelines and best practices related to combustible dust management. That said, NFPA 652 is not a regulation. But that doesn’t mean businesses can ignore the dust hazards in their facilities.

OSHA has a general-duty clause saying that employers are required to have a workplace safe from known hazards. Because NFPA has published a considerable amount of information related to combustible dust, combustible dust is a known hazard. “OSHA will often cite its general-duty clause when workplaces are not in compliance with the NFPA guidelines,” Cloney points out.

OSHA also has its Hazard Communication Standard (HCS) which outlines an employer’s responsibility to communicate hazards to workers. “There are also industry-specific guidelines OSHA has developed, such as its grain-handling standard,” Cloney says.

Another level of regulation ties to state and local jurisdictions. A state can choose to adopt OSHA’s federal regulations, adopt a state-level OSHA regulation, or develop its own regulation, perhaps through local fire or building codes.

Regardless, businesses need to know the laws they need to comply with. Failure to comply could lead to the following:

- Fines

- Stop work orders

- Inability to obtain insurance

In the event of a combustible dust fire or explosion, a business could also be exposed to various lawsuits. For example, Cloney points to a grain elevator explosion in Nebraska. The city’s disaster response efforts resulted in tens of thousands of dollars in expenses. The city ended up suing the elevator owner for financial reimbursement.

Aside from the financial repercussions of non-compliance, Cloney says businesses should first think about the human component.

“What are the ramifications of not following the NFPA’s guidance in the first place?” Cloney asks. The result could be something as catastrophic as an explosion that decimates an entire facility, as was the case with a sugar refinery in Port Wentworth, Georgia. More importantly, 14 people were killed and another 38 injured.

Horrific events such as that happen regularly. Cloney assembles an annual “Combustible Dust Incident Report”. There were 164 incidents in North America in 2017. That’s roughly three per week. Of those 164 incidents, 32 included an explosion. You can download these reports at Cloney’s website, DustEx Research – Incident Database (once you click through, scroll down toward the bottom of the page).

Combustible dust hazards can affect numerous types of industrial facilities. Great Lakes Power Vac assists in dust mitigation in a number of those settings. “We have several clients in the foundry industry, specifically those dealing with aluminum and gray iron where the dust created is highly reactive,” says Dan Bemi, director of business development for Great Lakes Power Vac, a Wisconsin-based provider of industrial cleaning and environmental services since 2004. “We also work in the grain handling industries where clients are dealing with a lot of organic product and have containment structures such as silos. We also have clients in food, plastics and chemical manufacturing, as well as power generation companies and fabricators.”

In all of these industries, and many more, a variety of industrial dust is created. Not all of that dust is necessarily combustible, but there’s a good chance that it is. Waiting for a fire or explosion to happen is not the best way to find out. Businesses should heed the guidelines offered by the NFPA and begin assessing the combustible dust hazards in their facilities — before it’s too late.

If you would like more information on combustible dust mitigation strategies and cleaning methods, be sure to contact us. Be sure to look for our next blog in this series, which will address how to assess the risk of dust explosions in your facility.